Wastewater contains a lot of valuable materials such as fat, oil, and grease (FOG) that can be further processed to produce useful fuels such as biodiesel. Utilizing these valuable materials could reduce the use of natural resources and subsequent carbon dioxide (CO2) emissions and hence, realize a circular economy. In the WOW project, a techno-economic assessment on biodiesel production from sewage sludge as substrate was performed which shows that a positive business case is possible.

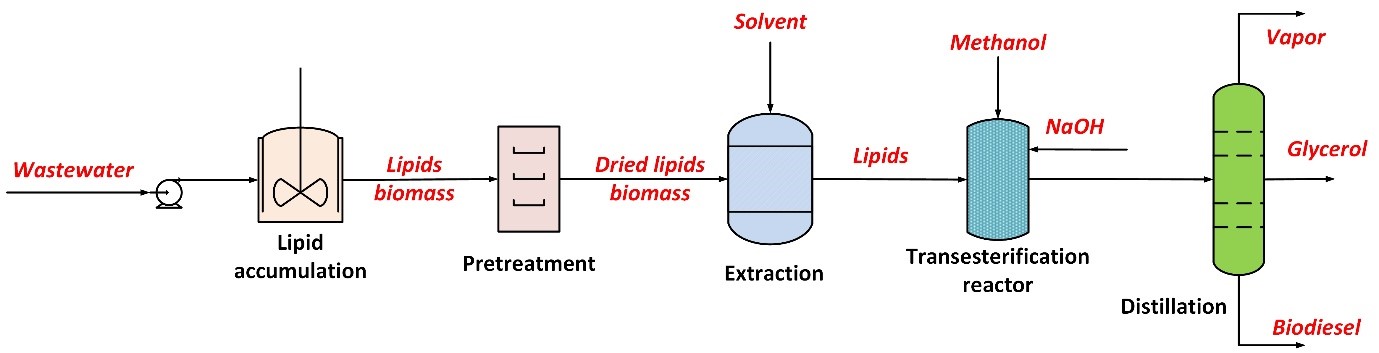

The biodiesel production value chain consisted of several steps including mixing, lipids accumulation and microbial growth, separation, drying, extraction, transesterification, separation, and purification of products as shown in Figure below. The minimum selling price (MSP) of biodiesel estimated in this assessment was €1.59/kg which is higher than the market price. Further comparison with the literature using various feedstocks also shows that the estimated MSP is relatively higher.

Parameters

Several technical and economic parameters affect the overall performance of the plant. The biomass recirculation back to the anoxic tank is the most influential variable. Lowering the recirculation from 90% to about 72% will result in the biodiesel MSP similar to the average market price. An optimum recirculation strategy should be developed without compromising the biomass requirement in the anoxic tank. An alternate biomass source can also provide the required biomass. This source can be from either the primary or secondary sludge of the sludge treatment plant (STP).

The next influential variable is the plant capital expenditure (CAPEX) in which the anoxic and aerobic tanks constitute 80% of the total CAPEX. Therefore, a lot of reduction in the CAPEX can be expected if these tanks are optimally designed or an alternate reactor configuration is employed. A 50% reduction in the CAPEX can reduce the biodiesel production cost by 23%. The plant scale represented by the wastewater inflow is also considered an influential variable. With an increase in the plant scale, the equipment size was also increased by a specific exponential relationship particular to each equipment. This resulted in lower operating expenses per unit plant capacity accounting for the economies of the scale factor. Factoring in the savings in the operating expenditure (OPEX) of an STP when a part of the wastewater stream is directed towards the biodiesel production plant will also reduce the costs to some extent.

Results

The results show that several parameters are needed to be improved in tandem to make biodiesel production from sewage economically feasible. The pilot plant developed in this project is innovative and has a new design. Thus, there will be deviations in the estimated results from the actual operation of the plant. There will be a learning curve that will help in utilizing the resources efficiently and optimizing the plant operation. The performance of this value chain compared to other biodiesel production plants indicate its future potential. Given the key variables and improvement strategies discussed above, a positive business case is possible. It would be interesting to investigate further since it has the potential for reducing the MSP by optimizing plant operation and efficient energy consumption.

> download the complete TEA report of biodiesel

For more information please contact Mohammed Nazeer Khan > mohammednazeer.khan@vito.be

Figure: Biodiesel production from sewage