Anja Tusch, Wolfgang Breit, Robert Adams

Technical University of Kaiserslautern

One of the objectives of the project SeRaMCo (Secondary Raw Materials for Concrete Precast Products) is the development of concrete mixtures for precast elements for structural and non-structural purposes, especially pavement elements. A special challenge is the use of recycled aggregates from unknown origin consisting of variable fractions of crushed concrete, crushed brick, asphalt, ceramics and light-weight components. Compared to normal aggregates, these materials are expected to variate a lot in their constituting components as well as in their properties e.g. density, strength and durability.

The project aims to develop two different concrete mixes containing recycled aggregates from unknown origin. On the one hand, a mix for structural purposes which covers the strength classes up to C 30/37 and the exposure classes XD 3, XC 4 and XF 4, and on the other hand a mix for the production of pavements, which has to match the requirements of EN 1338 [2]. This article investigates the influence of recycled aggregates on the compressive strength and splitting tensile strength.

Test program

Aim

The test explored the impacts of recycled aggregates on the properties of fresh concrete, especially density and consistency/workability, as well as the properties of hardened concrete, especially compressive strength and tensile splitting strength.

Materials

The materials used to perform the test were recycled concrete aggregates of unknown sources and mixed aggregates, classified as Type A and Type B conferring to EN 206 [3] with the exception of the higher asphalt proportion within the recycled concrete aggregates, exceeding the limit of 1 %. The aggregates were washed and separated into three fractions (2/6 mm, 6/14 mm and 14/22 mm), each. For the fraction 0/2 mm natural sand was used. The properties of the aggregates such as density and especially water absorption were determined as well as the grain size distribution. Concrete mixes were made using ordinary Portland cement CEM I 42.5.

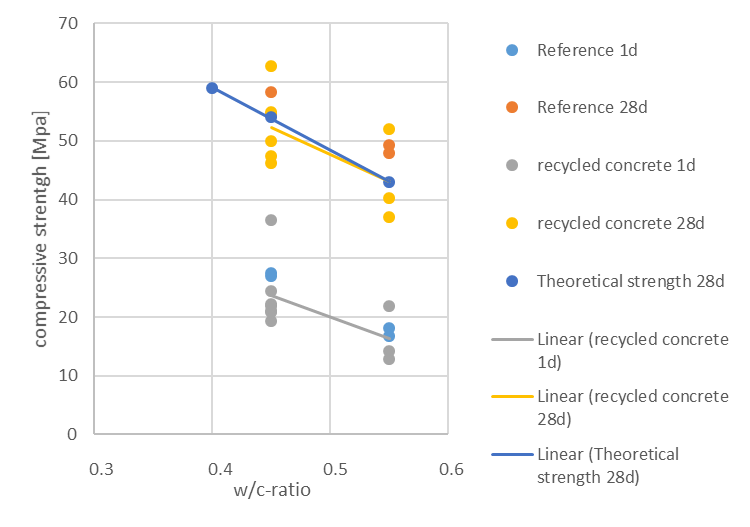

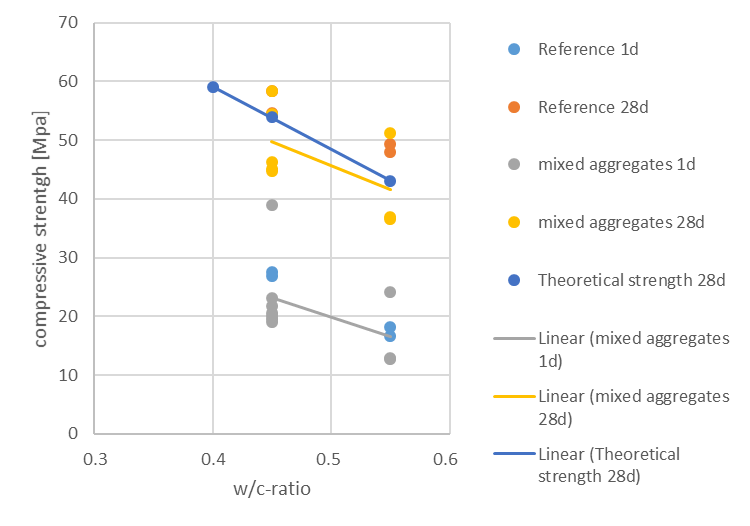

Concrete for structural purposes

For the development of a concrete mix containing recycled aggregates, two different w/c-ratios (0.45 and 0.55) were tested. The grain size distribution corresponded in all cases to grading curve A16/B16 according to German standard DIN 1045-2. In all mixes, coarse aggregates were totally replaced by recycled aggregates. For the fraction 0/2 mm natural sand was used. The water absorption of the recycled aggregates was taken into account by adding the sucking water to the mix. A mixture containing 100 % natural aggregates was used as reference.

Concrete for pavements

Beside the compressive strength, the concrete meant for pavement production must match special requirements concerning the tensile splitting strength and durability, especially abrasion and freeze-thaw resistance. Furthermore, the problem of alkali silica reaction (ASR) has to be taken into account. This could lead to a limitation of cement content or the use of cement with low effective alkali content.

In addition, the production of pavements differs from the production of other precast products. In fact, for the former, concrete mixes with an earth moisture consistency are normally compacted within a sophisticated process consisting of vibration and an additional compressive force.

Results and discussion

Promising results came out from the test. As the two graphs in figure 1 show, the concrete mixes tested for the standard concrete show only insignificantly lower values in compressive strength than the reference concrete. This applies for the 1 d-compressive strength as well as for the 28 d-compressive strength.

The first test for the pavements showed that it is possible to reach the required tensile splitting strength of 3.6 MPa. Furthermore, first tests regarding the abrasion resistance promisingly show that it is possible to also reach the requirements for the mechanical durability.

The next step in this project will be to consolidate these results and to check further requirements as freeze-thaw resistance and carbonation.