By N. TAZI, R. IDIR and A. BEN FRAJ

Cerema, Project team DIMA

Construction is essential to the development of countries, even during a global health crisis. Billions of tons of materials are continuously consumed to satisfy the world’s insatiable demand. However, this trend in materials use leads to a significant depletion of natural resources and will converge towards a tipping point. Fortunately, solutions exist nowadays to substitute natural resources with recycled materials. These solutions address the challenge of resource depletion as well as the valorization of waste from the construction sector. Cerema, within the SeRaMCo Interreg project, is working on several paths to use recycled concrete made of recycled materials and thus reduce its environmental impact. This project aims at increasing the use of recycled aggregates and fines in a real circular economy. This article resumes some of these ways addressed in our previous research article and focuses on the effects of CO2 uptake of recycled aggregates.

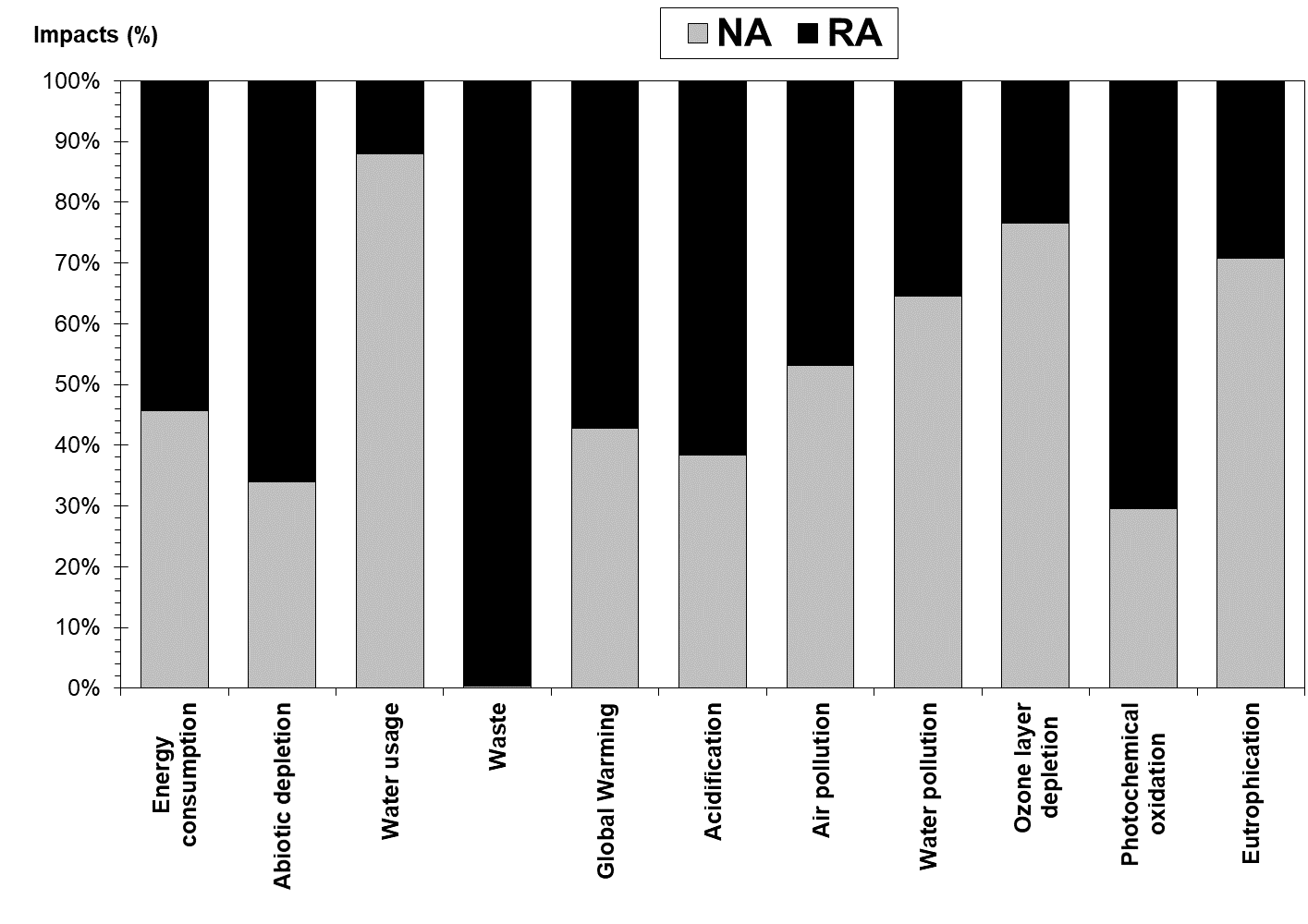

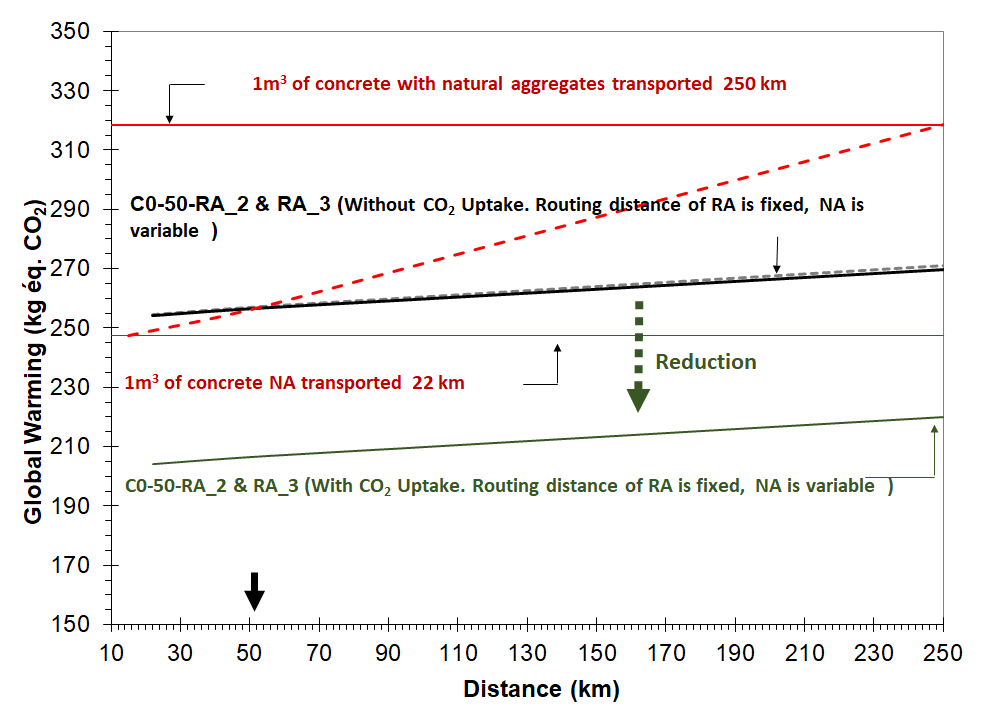

Mitigating the environmental impact of recycled concrete could be achieved by optimizing the recycling process of construction & demolition wastes, considering the preservation of natural resources by using recycled materials or by considering the Carbone uptake of recycled aggregates. The latter is performed by taking into account the carbonatation of recycled aggregates. Recent results estimate up to 0.05-ton CO2/ton uptake of recycled aggregates, which would reduce consequently the “global warming” indicator when performing a life cycle analysis of these aggregates. While the environmental impacts of recycled aggregates have been assessed previously (Figure 1), an extra potential reduction of these environmental effects could be achieved when considering the following benefits of using recycled aggregates:

- Valorizing trivial industrial wastes in the recycling process;

- Considering the CO2 uptake and how it affects the “global warming” indicator of recycled aggregates.

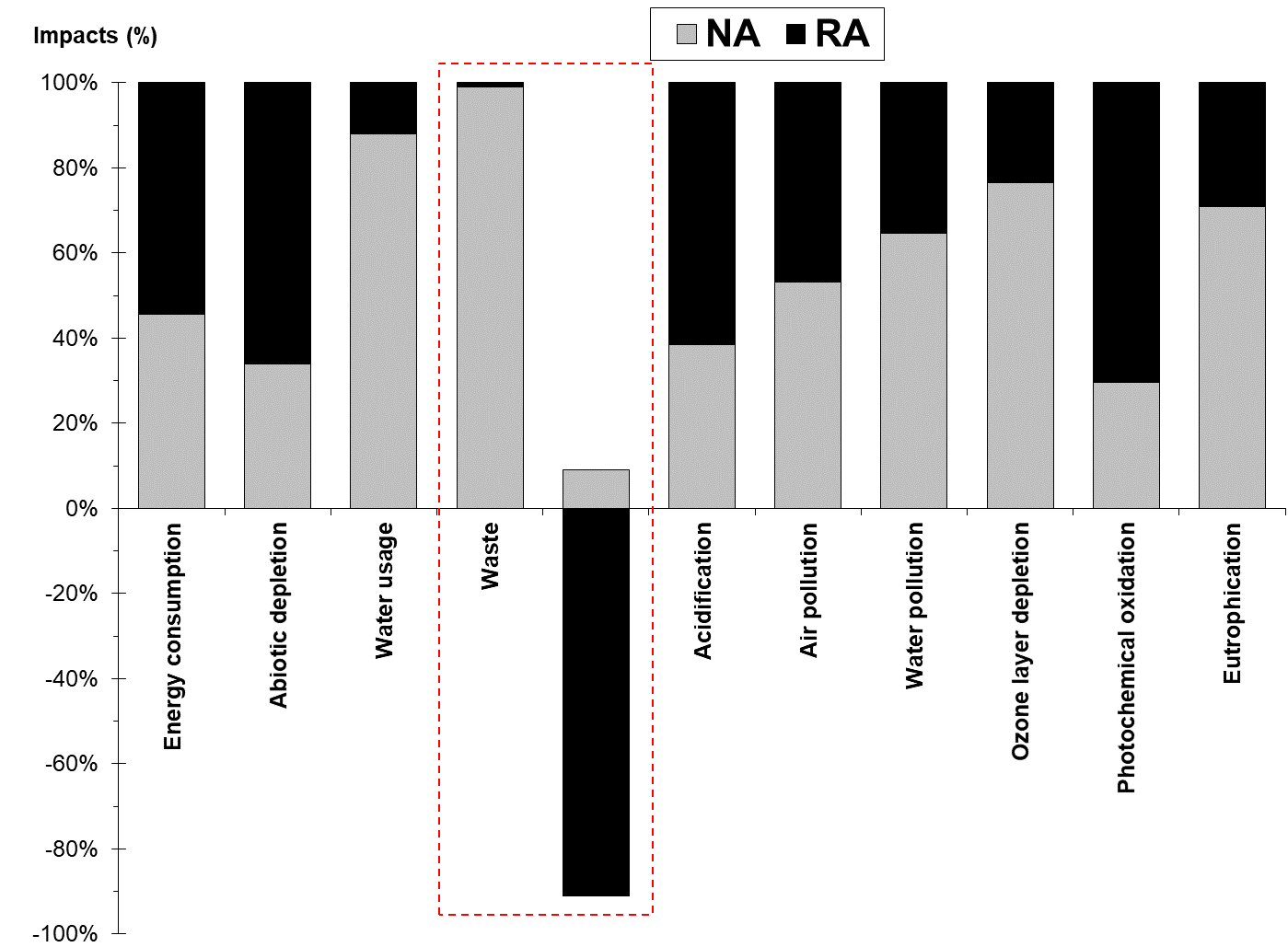

Thus, as shown in Figure 2, the environmental impacts of recycled aggregates are mitigated, and it is then suitable to use these recycled materials as a substitution to natural aggregates.