Food Processing SME Mariën Bakkerij Producten N.V. and manufacturer of innovative health, sport and fitness products Aminolabs, are well on their way to cobot adoption, having made it through the COTEMACO SME Support programme.

The SME support programme guides manufacturing SMEs through the process of adopting collaborative robotic and shop floor digitalisation technologies, from the exploration of technological opportunities to the detailed definition of a business plan.

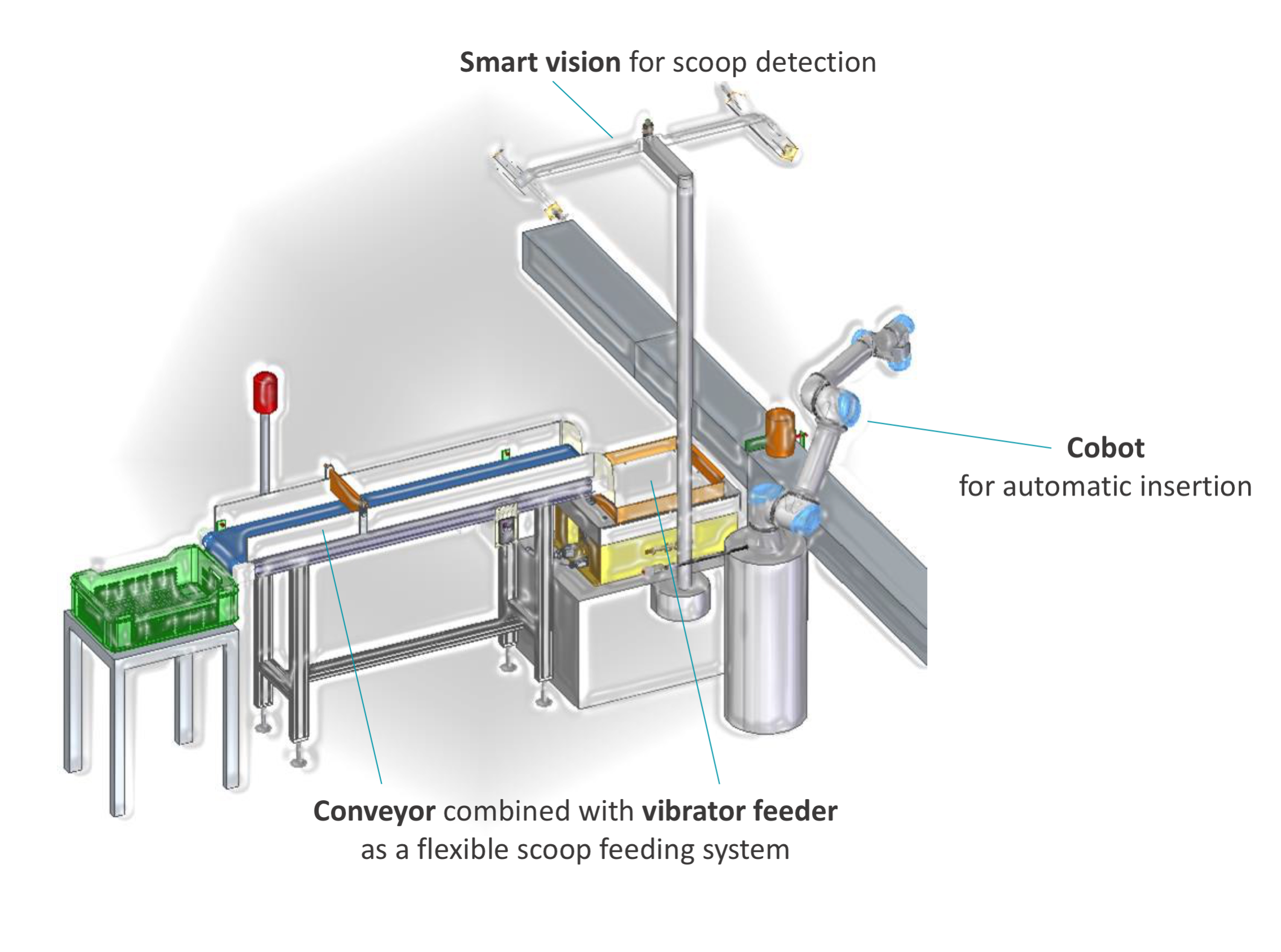

Mariën bakery solution: Mobile Cobot system with integrated smart sensor systems

Mariën Bakkerij Producten N.V. was supported by the Food Tech Brainport team, which assessed their challenges, walked the company through cobot opportunities, helped to set up an implementation plan, and even managed to secure funding for cobot integration in the Mariën factory. Both Mariën and their technology provider - Van Wees Waalwijk - will receive a grant of €60.000 from the European Horizon2020 S3FOOD programme.

The company produces various types of bread, cakes and tarts, which for employees, involves a lot of bending down and lifting up heavy trays loaded with dough. Employees also have to carry out many dull monotonous repetitive tasks such as a glazing bread with egg yolk or notching baguettes. As it is becoming increasingly hard to find new staff willing to do these tasks, Mariën set out to automate them, with flexible mobile cobots that can perform multiple actions and can be deployed at various working locations in one day.

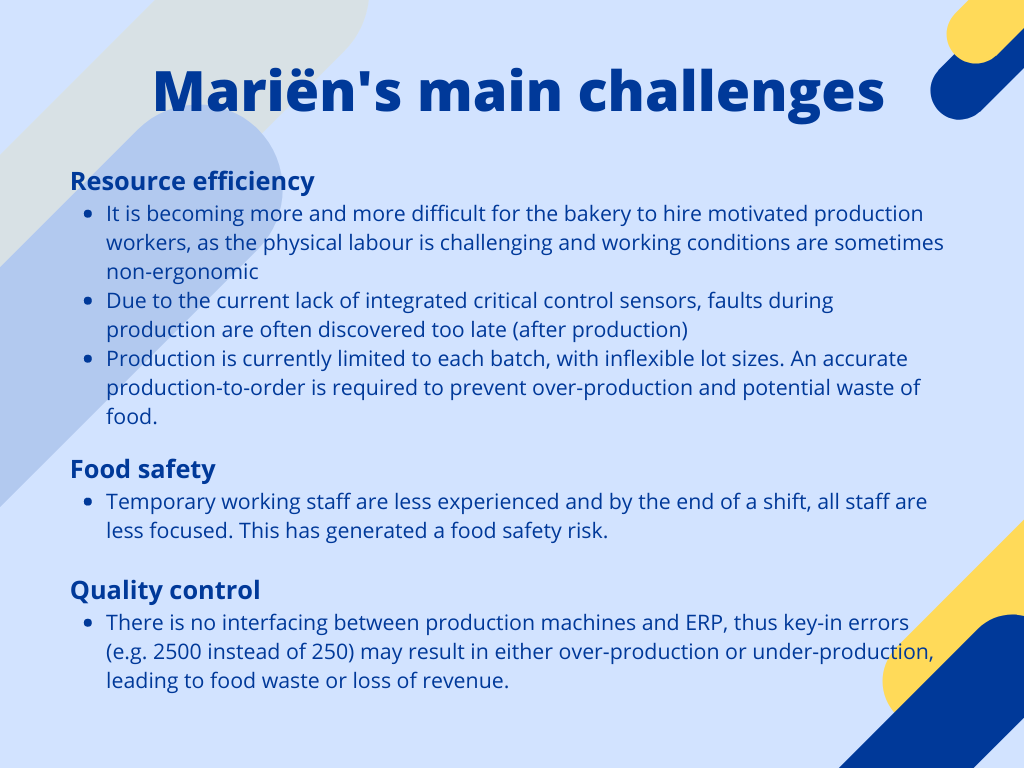

Food Tech Brainport identified a mobile cobot system solution to address the company’s three main challenges: resource efficiency, food safety and quality control.